The Environmental Benefits of Choosing Alternative PVC Wood

Understanding Alternative PVC Wood

As environmental concerns continue to grow, many individuals and businesses are looking for more sustainable building materials. One such innovation is alternative PVC wood, which offers an eco-friendly option compared to traditional wood products. This material is made from recycled plastics and other eco-friendly components, providing a sustainable and versatile solution for various applications.

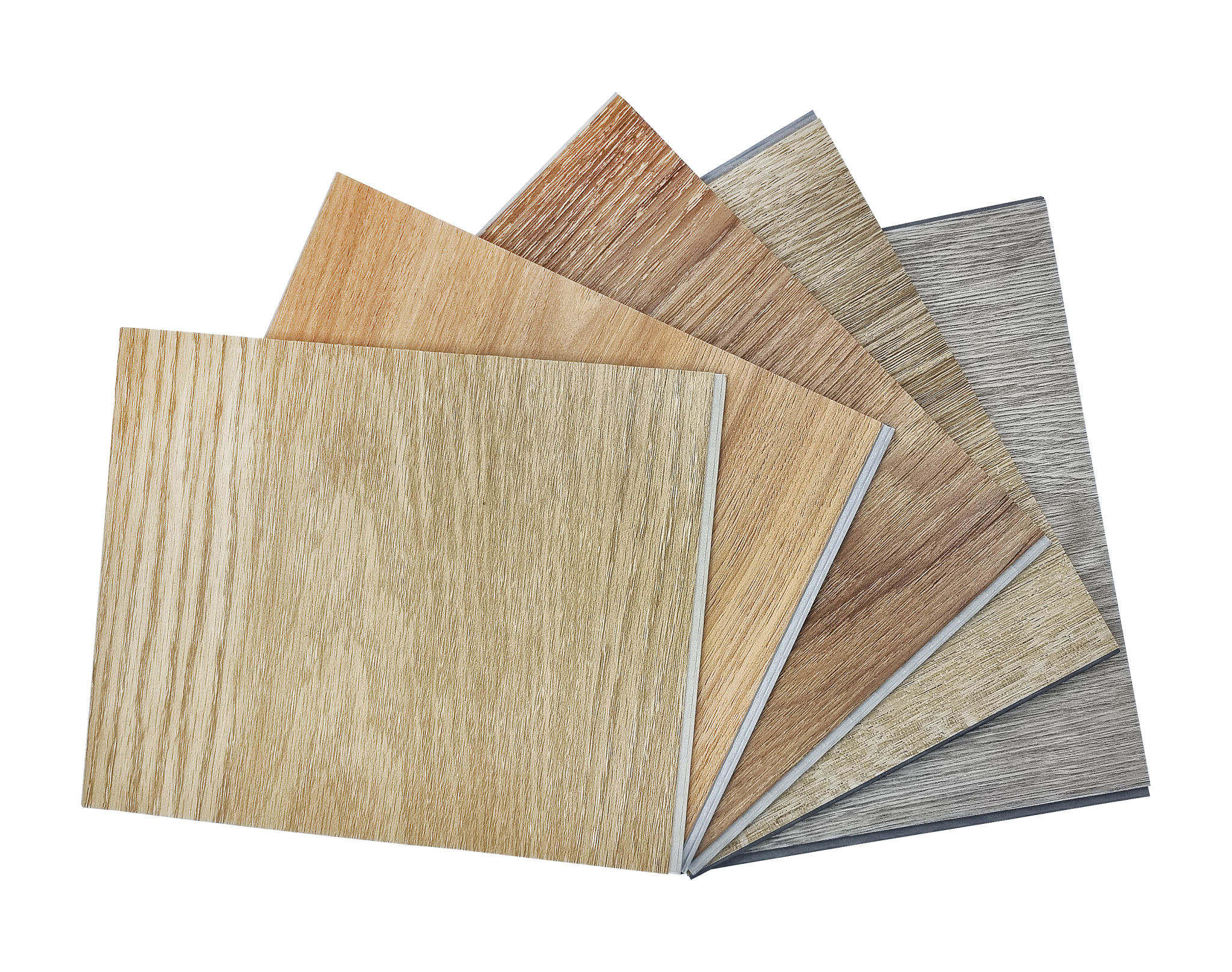

Alternative PVC wood mimics the appearance and texture of natural wood while offering advantages that traditional wood cannot. It's a durable, low-maintenance option that resists moisture, decay, and pests, making it an excellent choice for outdoor applications.

Reducing Deforestation

One of the most significant environmental benefits of choosing alternative PVC wood is its ability to help reduce deforestation. Traditional wood harvesting often leads to the destruction of vital ecosystems and loss of biodiversity. By opting for PVC alternatives, we can significantly decrease the demand for natural wood, thus preserving forests and their inhabitants.

Forests play a crucial role in absorbing carbon dioxide from the atmosphere. By protecting these natural resources, we can help mitigate climate change impacts. The use of alternative PVC wood supports this effort by reducing the need to cut down trees for building materials.

Minimizing Waste with Recycled Materials

Alternative PVC wood is often made from recycled materials, which helps reduce waste in landfills. By repurposing plastic waste into building materials, we can decrease the environmental burden associated with plastic pollution. This recycling process not only conserves resources but also reduces the energy required to produce new materials.

Additionally, using recycled materials helps lower greenhouse gas emissions associated with the production and transportation of raw materials. By choosing alternative PVC wood, you contribute to a more circular economy that prioritizes resource efficiency.

Energy Efficiency in Production

The production process for alternative PVC wood is generally more energy-efficient than that of traditional wood products. Manufacturing this material requires less energy and water, leading to a smaller carbon footprint. The energy savings achieved during production can contribute significantly to reducing overall environmental impact.

Furthermore, the manufacturing process for alternative PVC wood often produces fewer emissions and pollutants compared to traditional wood processing. This means cleaner air and water, ultimately benefiting both the environment and human health.

Long-lasting and Low Maintenance

Another advantage of alternative PVC wood is its longevity and low-maintenance nature. Unlike traditional wood, which may require frequent treatments and repairs due to weathering or pest damage, PVC wood is resistant to these issues. This means fewer replacements and repairs over time, reducing waste and conserving resources.

The durability of alternative PVC wood also means that structures built with this material have a longer lifespan, further minimizing environmental impact through reduced material consumption and waste generation.

Conclusion

Choosing alternative PVC wood offers numerous environmental benefits, from reducing deforestation to minimizing waste and energy consumption. As awareness of sustainable practices grows, this innovative material presents a viable option for those seeking eco-friendly building solutions. By opting for alternative PVC wood, you can contribute to a more sustainable future while enjoying the durability and aesthetic appeal of this versatile material.